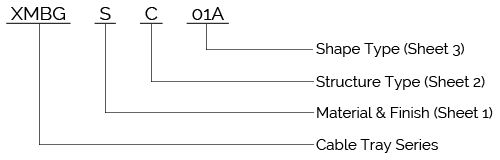

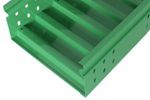

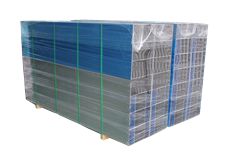

Perforated Corrugated Cable Tray

■ New generation cable tray ■ Excellent loading capacity ■ Light weight ■ Energy-saving ■ Long working life ■ Competitive price Optimize design for bottom & side by Finite Element Method (FEM), increase inertia moment of bottom to enhance loading capacity, assemble by mechanical arm & laser welding assure fastness...